PRODUCT DESCRIPTION

-

The new generation desktop soldering robot for Industry 4.0 and IoT.

-

UNIX-DF Series have improved its network function and robotic motion.

-

Three types, according to PCB size. These are also applicable and optimized for laser soldering.

-

It can connect with the network, which can visualize each soldering process and result.

-

The additional two axes facilitate penetration angles or rotate PCB, which make difficult soldering component possible.

UNIX-DF204S

Compact type

・Working area: 200mm×210mm

・New and improved heater

・LAN (Ethernet), COM port

・X,Y axis: 600mm/sec

・Z axis: 250mm/sec

・Separated soldering controller

UNIX-DF304S

Middle type

・Working area: 300mm×275mm

・New and improved heater

・LAN (Ethernet), COM port

・X,Y axis: 900mm/sec

・Z axis: 400mm/sec

・Built-in soldering controller

UNIX-DF404S

Wide type

・Working area: 400mm×365mm

・Supports M-size PCBs

・New and improved heater

・LAN (Ethernet), COM port

・X,Y axis: 900mm/sec

・Z axis: 400mm/sec

・Built-in soldering controller

-

Improved network functions for industry 4.0

-

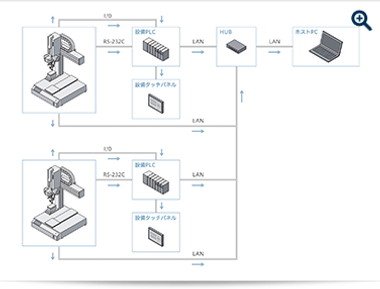

Connecting to factory network and making operation visible in real time.

-

Supporting data export and external process control via LAN or COM port.

-

Special monitoring software can remotely monitor operation status.

-

The real-time monitoring can prevent defective products.

-

Robots are controllable with connecting to PLC and with control commands.

-

Two additional axes enable complex PCB soldering easy and flexible.

-

Total up to six axes are available.

-

External devices are integrally controllable with the batch operation of the robot.

-

Various motions such as component rotation, PCB reversal, head angles, rotation of cylindrical parts, cable suppression, etc.

-

Space saving and easy to set up.

-

Highly improved productivity with the new heater.

-

Higher accuracy and improved temperature characteristics.

-

Much more accurate temperature measurement has been achieved by placing heat sensor at the tip of the tip.

-

Quick temp. recovery achieves higher operational efficiency.

-

The heater and the tip are separated and can be replaced individually.

-

Poka Yoke function prevents to make mistakes of installing a soldering tip and its direction.

Industry 4.0. Data management of each soldering process:

By connecting DF monitoring software, various soldering processes such as temperature, program execution and so on are visualized and converted into numerical data.

For example, observing the temperature during soldering, if irregular temperature change or program execution occurred, the monitoring system captures their irregularity and can notify errors.

Furthermore, connecting to the Internet/intranet, the system can notify error and can send alert to the registered email. Such real-time observation enables you to immediately respond to operation errors and defects.

Any data can be exported with CSV format. Various operational log data from each process can be useful for investigating and exploring for further productivity improvement.